Art Supplies - Craft Kits - Nice Paper - Clever Toys

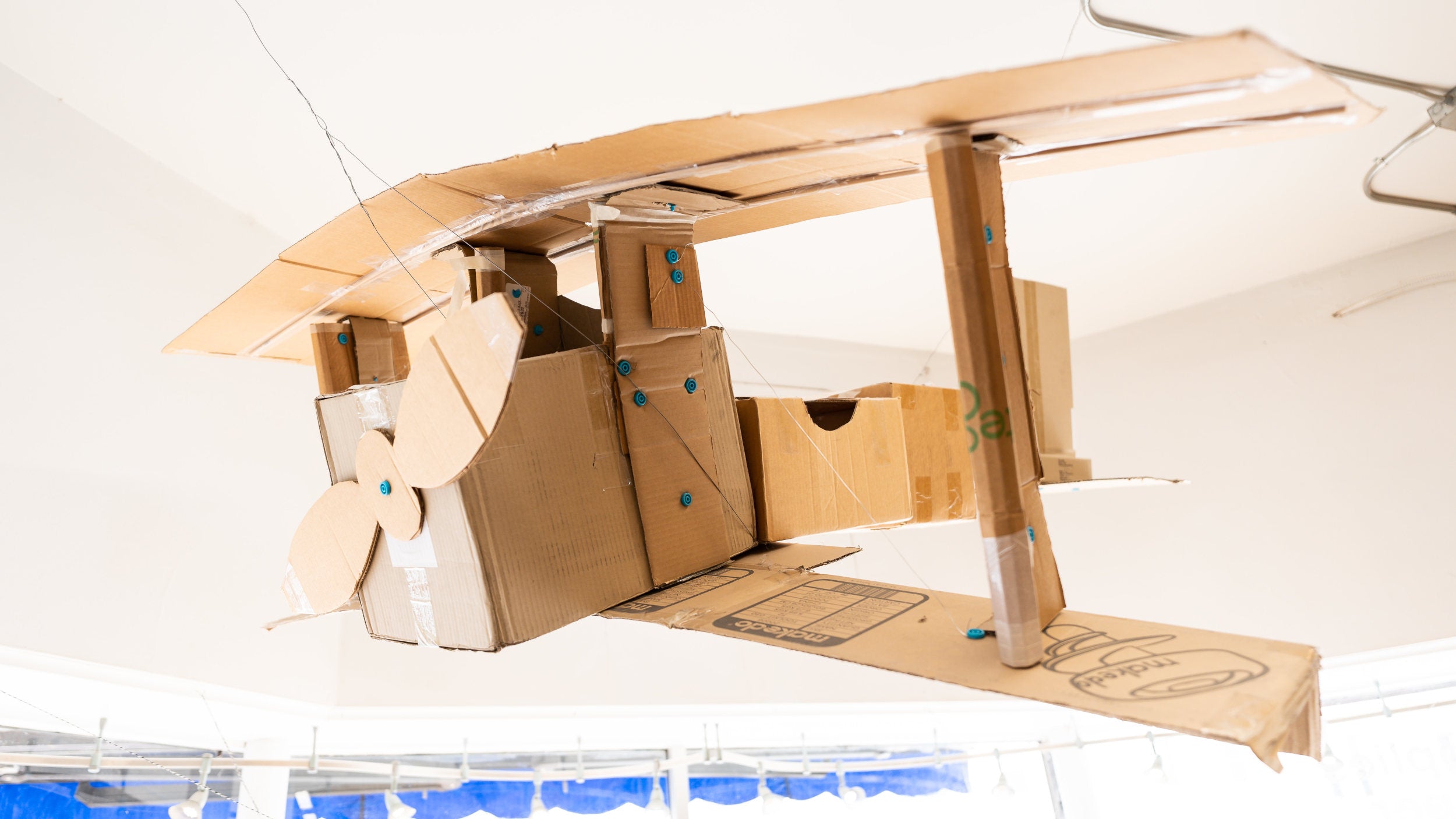

Do you have bored kids? Has watching Bob Ross re-runs fired up your need to fill a canvas? Do you need a gift for the creative weirdo in your life? Are YOU the creative weirdo? At Cardboard Robot, we can help you get what you need to feed your inner maker.

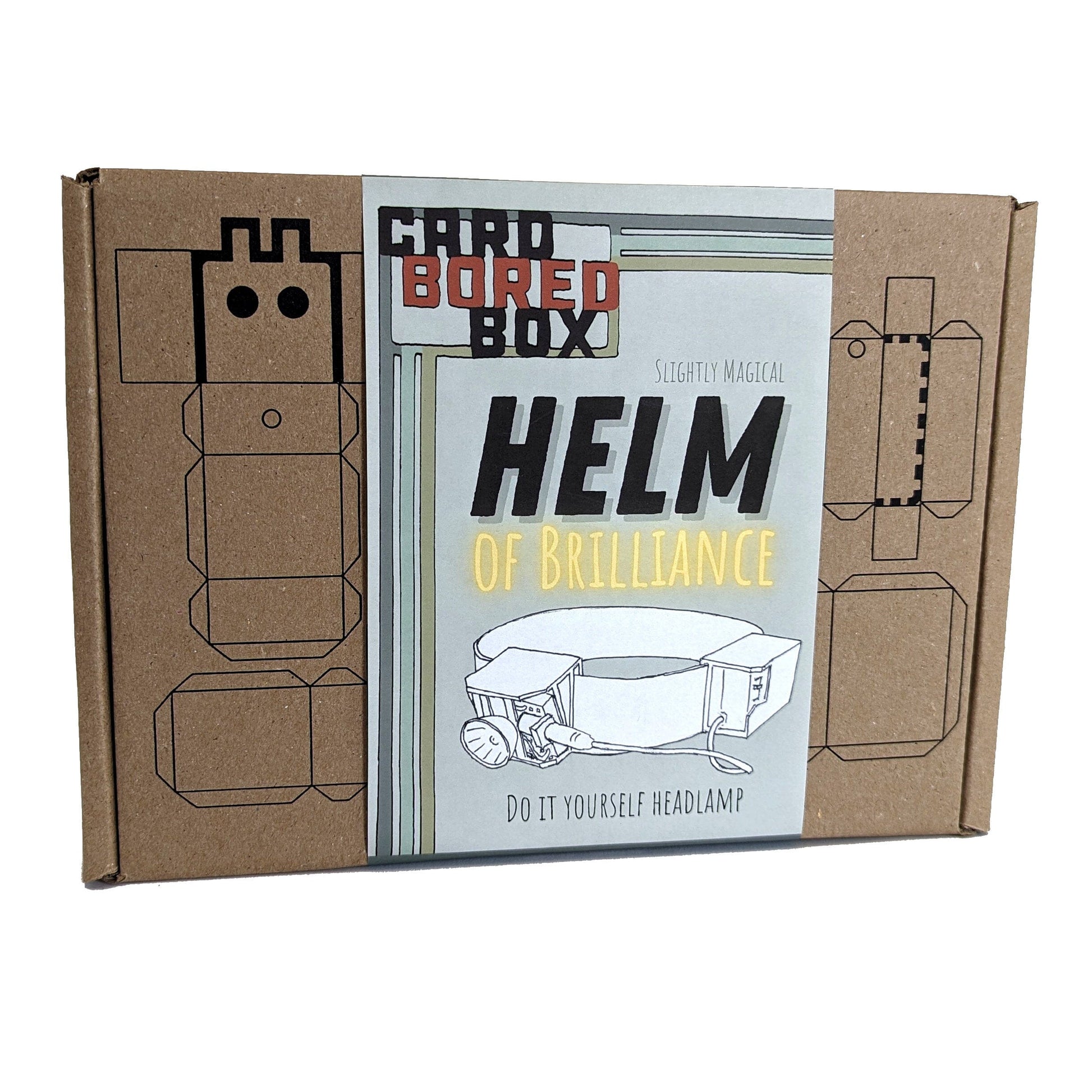

Cardbored Box

Helm of Brilliance

Regular price

$32.00 USD

Regular price

Sale price

$32.00 USD

Unit price

per

Reviews

-

Karen

"Review from my son: 'A fun and creative place, nice staff, and a great selection of crafty materials'"

-

Brent

"I wish I could say that I love taking my kids here but I don’t. It just distracts me from shopping for myself. When in Decorah you have to checkout Cardboard Robot."

-

Jean

"Thanks for providing a way a "long-distance" grandma can get a great gift for her grandson."